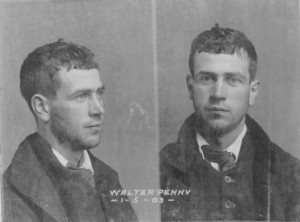

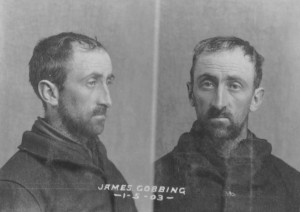

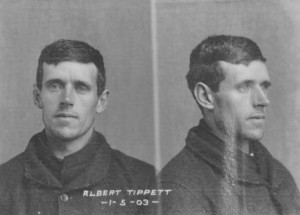

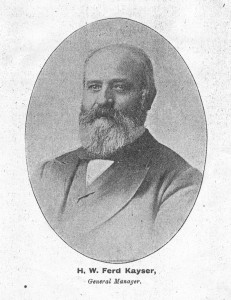

In 1903 three Waratah men—Walter Penney, James Cobbing and Albert Tippett—were gaoled for five years for receiving tin stolen from the Mount Bischoff Company. Yet the court case looked more like a showdown than a trial—the culmination of a 25-year feud between Ferd Kayser and his Cornish detractors. The three accused men worked the Waratah Alluvial plant on the Waratah River, which recovered tin lost into the water by the Mount Bischoff Co dressing sheds. They claimed that the tin they were accused of stealing had simply been retrieved from the bottom of the Waratah Alluvial dam on the river. The prosecution case was that the tin had been stolen directly from the Mount Bischoff Co dressing sheds earlier when Penney, Cobbing and Tippett worked there. At the dock, Kayser, the Mount Bischoff Co’s high profile general manager slugged it out with the canny Cornish tin dresser Richard Mitchell. Their on-going argument was ostensibly about the better ore processing method—German or Cornish. Yet in truth it was more about ego, reputation and the struggle to make a living.

The defence case rested on being able to show that the Mount Bischoff Co dressing sheds and its own tin recovery plants on the Waratah River were ineffectual, and that Mount Bischoff Co staff who had identified the stolen tin as being theirs were incapable of doing so. In speaking for the defence, Mitchell attacked Kayser’s ‘antiquated’ dressing machinery, claiming that his own plant (he was manager of the Anchor tin mine in the north-east) was ’50 years ahead of it’.[1] Laughably, Kayser failed to even identify Mount Bischoff Co dressed tin when it was placed in his hand at the dock. For five years he had been living away from the mine in Launceston as general manager, allowing John Millen to run the mine. Perhaps he was so out of touch that he had forgotten the appearance of the dressed tin he had produced for 23 years.

A succession of Cornish miners had been nipping at his heels throughout that time. Cornish miners asserted their superiority as hard-rock miners, exploiting their Cornish ethnicity as an economic strategy.[2] Being Cornish was their ‘brand’. Cornish miners were famous for their instinctive, canny style of management. They grew up mining from childhood, learning their craft on the job, without a formal mining education.[3] At Mount Bischoff Cornishmen they had tried to enhance this reputation by operating small retrieval plants, ‘lifting the crumbs from the rich man’s table’, that is, they had realised that the richest material on their leases was not lode tin or alluvial tin but escaped Mount Bischoff Co ore. The first to recognise this was the Waratah Tin Mining Company (Waratah Tin Co). Tailings from the Mount Bischoff Co sluice boxes emptied into a creek which ran through the Waratah Tin Co property into the Waratah River. In about 1878 that company’s Cornish tin dresser, Richard Mitchell, switched from working its tin lode to extracting ore from the creek.[4] Other Cornish tin dressers—ASR Osborne, William White and Anthony Roberts—followed suit. Their plants, the East Bischoff Company, Bischoff Tin Streaming Company, Bischoff Alluvial Tin Mining Company/Phoenix Alluvial Company and Waratah Alluvial Company, bore nicknames that suggested they were ‘shearing’ the Waratah River—the ‘Catch ‘em by the Wool’, ‘Shear ‘em’, ‘Shave ‘em’, ‘Hold ‘em’ and the ‘Catch ‘em by the Wool no. 2’ respectively.

To many, Cornwall was a byword for simplicity, economy and improvisation. However, to Kayser, a champion of technology, Cornwall, the so-called ‘cradle of the Industrial Revolution’, was a ‘Luddite’. Antiquated Cornish mining methods were his favourite hobbyhorse. One of his first actions on taking over the management in 1875 was to sack the Mount Bischoff Co’s Cornish ore dresser Stephen Eddy, whose improvised appliances, he said, included ‘the hand-jigger and all the old primitive appliances his great grandfather used’.[5]

However, Kayser could not deny that there was plenty of ore for the Cornish tin dressers to retrieve. It has been estimated that the Mount Bischoff Co dressing sheds alone lost 22,000 tons of metallic tin into the Arthur River system up to 1907—30,000 tons by 1928. To put that in perspective, the Mount Bischoff Co produced about 56,000 tons of metallic tin, meaning that about one-third of the tin ore mined at Mount Bischoff ended up not in smelted bars for shipment to London, but in the Arthur River system. After deriding his Cornish rivals for years, in 1883 Kayser established the first of two tin recovery plants of his own on the Waratah River. The Ringtail Sheds at the base of the Ringtail Falls on the Waratah River stood on the old Waratah Tin Co block, where Richard Mitchell had set up the very first tin recovery operation five years earlier. Well-graded access tracks to the Ringtail Sheds were constructed from both sides of the Waratah River, the track on the western side being used to pack the ore out from the sheds.[6] These formed a loop by meeting at a foot bridge across the river just above Ringtail Falls, the site of the sheds. They are still used today to visit the Mount Bischoff Co Power Station which was afterwards built below the sheds. However, so much tin remained in the Arthur River system that in the 1970s the idea was entertained of dredging not just the river but coastal deposits outside the river mouth.[7]

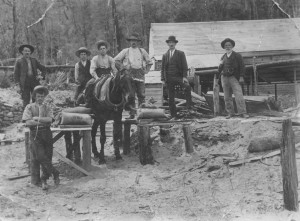

(The mugshots above are from GD63-1-3, Tasmanian Archive and Heritage Office.)

[1] ‘Alleged theft of tin ore’, Daily Telegraph, 22 April 1903, p.8.

[2] Philip Payton, Cornwall: a history, Cornwall Limited Editions, Fowey, Cornwall, 2004 (originally published 1996), p. 234; Ronald M James, ‘Defining the group: nineteenth-century Cornish on the North American mining frontier’, in Cornish studies: Two (ed. Philip Payton), University of Exeter Press, Exeter, 1994, cited by Philip Payton, Cornwall: a history, p.234.

[3] Geoffrey Blainey, The rush that never ended: a history of Australian mining, Melbourne University Press, 1978 (first published 1963), p.244.

[4] HW Ferd Kayser, ‘Mount Bischoff’, Proceedings of the Australasian Association for the Advancement of Science, no. IV, 1892, pp.350–51.

[5] HW Ferd Kayser, ‘Mount Bischoff’, p.346.

[6] ‘Alleged theft of tin ore’, Daily Telegraph, 21 April 1903, p .4.

[7] ‘Tin worth $45 million in Arthur River’, Advocate, 10 May 1973, p. 1.